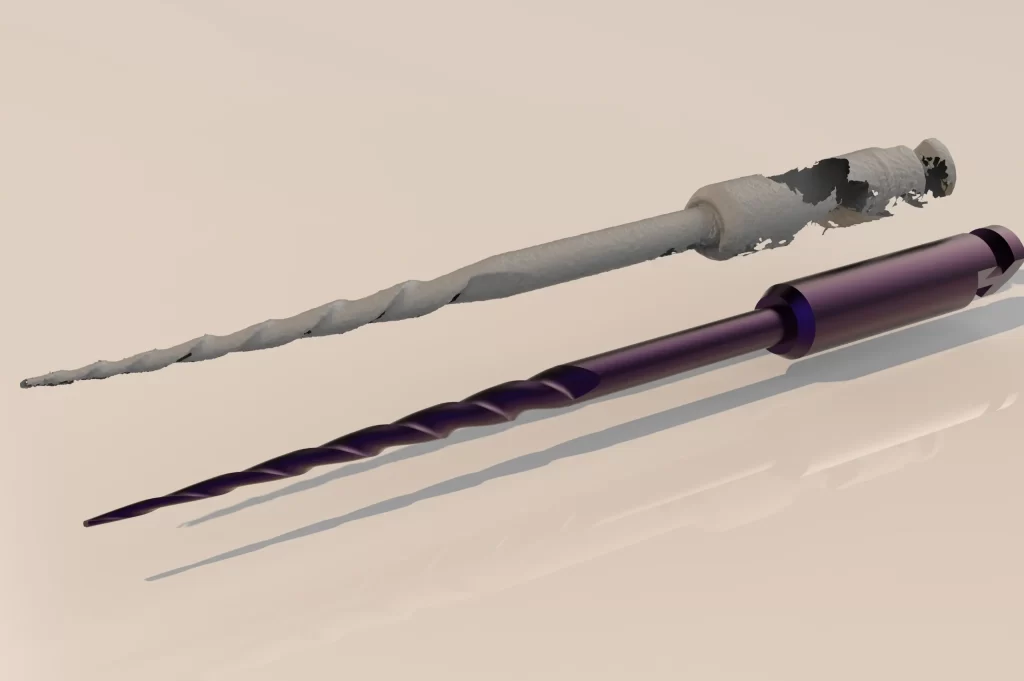

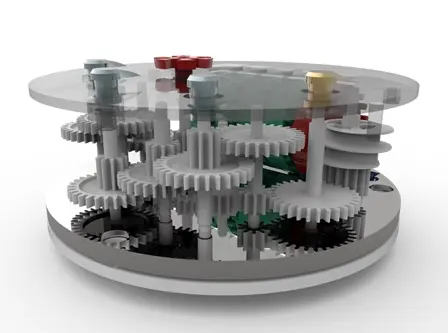

Solving the design and production codes of the product or system. This is the reason why we define this method as “REVERSE ENGINEERING”. It is a reverse examination of the work done starting from the concept phase of the product to reveal how, for what purpose, with what production methods and in what way the mechanical design was made. The primary purpose of the method defined as Reverse Engineering is to reveal the design and production history of the product in detail. In addition to examining existing products, the Reverse Engineering method is used to create a new concept and to develop a better product for the same purpose with a different approach. This method, which helps create quality, advanced technology, more effective and low-cost products by providing different perspectives on existing products, provides speed and convenience in creating road maps for companies that will develop new products.

Reverse Engineering is used to create infrastructure in Product Development, Benchmarking and Value Engineering studies. It constitutes the basic infrastructure for testing existing, competing, equivalent and similar products, especially in development projects.

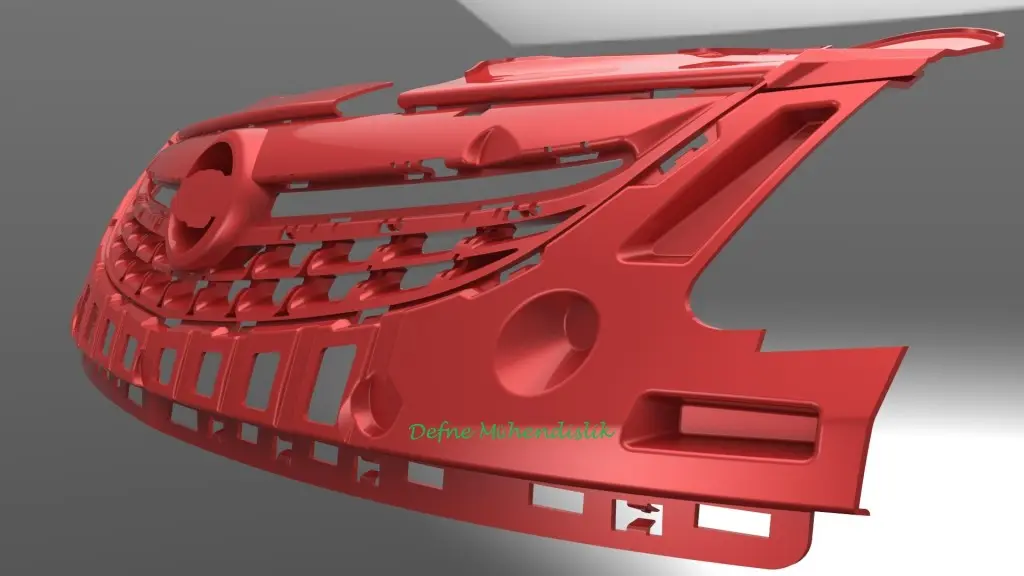

Our expertise and experience enable us to provide accurate, high-quality and fast solutions to our customers in projects where different specializations of engineering such as construction, design, development, analysis and materials come together and a team work takes place.

Reverse Engineering (RE); This method, also known as ‘Reverse Engineering’, comes from the English word ‘Reverse Engineering’ (RE). It is defined in dictionaries as follows:

To discover the product by disassembling it in detail and subjecting it to testing and analysis in order to produce a similar one.*

Examining a product that has emerged and creating its design. Then it is used to make other products with the same design. Software refers to the methods used to understand how a software does a job.**

Reverse Engineering (RE) of a device, object or system; It is the process of discovering its structure, function or operation through an inferential reasoning analysis. Dismantling the machine or mechanical device, electronic component, software program etc. and detailing the working principles includes analysis

www.merriam-webster.com

www.eksisozluk.com

http://tr.wikipedia.org

The product to be developed or different products with similar functions

by comparing products and comparing them with each other

It is necessary to reveal the differences of the products. companies

SWOT in business schools that they put forward in their business plans

The comparison method taught under the name of analysis is applied to these products.

Finding creative solutions that will make a difference in the market by applying

It will be much easier. Positions of products with SWOT analysis

their position in the market so that the company can reach its target with its new product.

It clearly reveals the steps that need to be passed.

S – Strength = Strong sides

W – Weekness= Weaknesses

O – Opportunity= Opportunities it creates

T – Threat = Threats Posed

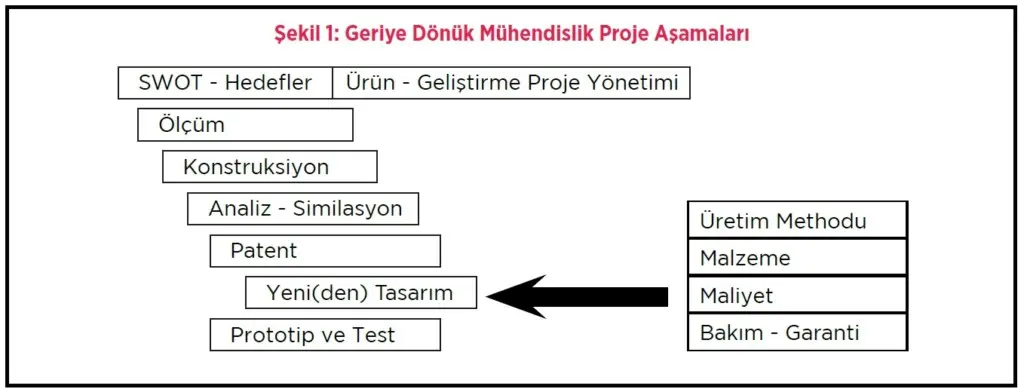

Project with an approach that reveals the SWOT features of the products

improvements or innovations to be made when starting

It becomes clear what is happening. Retrospective Engineering

Project steps and method of work, individual approach to each project

Even if it requires it, it is generally done with a simple upper plan. This

In planning, a Sherlock Holmes-style review is made on existing products.

revealing the details with this approach and making use of them

It is necessary to develop innovations. Creator who will add value to the product

functionality in a short time with lower cost with approaches

will be possible to obtain.