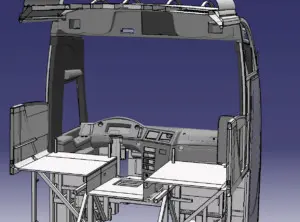

Product Development studies include the design and production processes of the existing product with more functionality and lower cost. It can also be considered as product design, but we classify the work done on an existing product as product development. Reverse Engineering studies are carried out for traded products or products that will be marketed through localization. 3D Measurement

Product development is a definition we make for the updating, localization, development, cost optimization and similar studies of the product that the company currently produces or trades.

The company may want to introduce a product to the market in a new field where it analyzes that competition will be appropriate. At this stage, our company contributes to the creation of competitive and innovative products by examining existing products in detail and catching new trends. We carry out innovative product development projects in different sectors with our knowledge of over 16 years of experience.

In product development studies, possible competitors of the company’s current product are analyzed using the Reverse Engineering method. You can find the details of the reverse engineering study here. The basis of any development work to be carried out, whether on the company’s own product or on rival products, should be based on reverse engineering analyses. In this way, the direction of current products and trends can be determined more clearly.

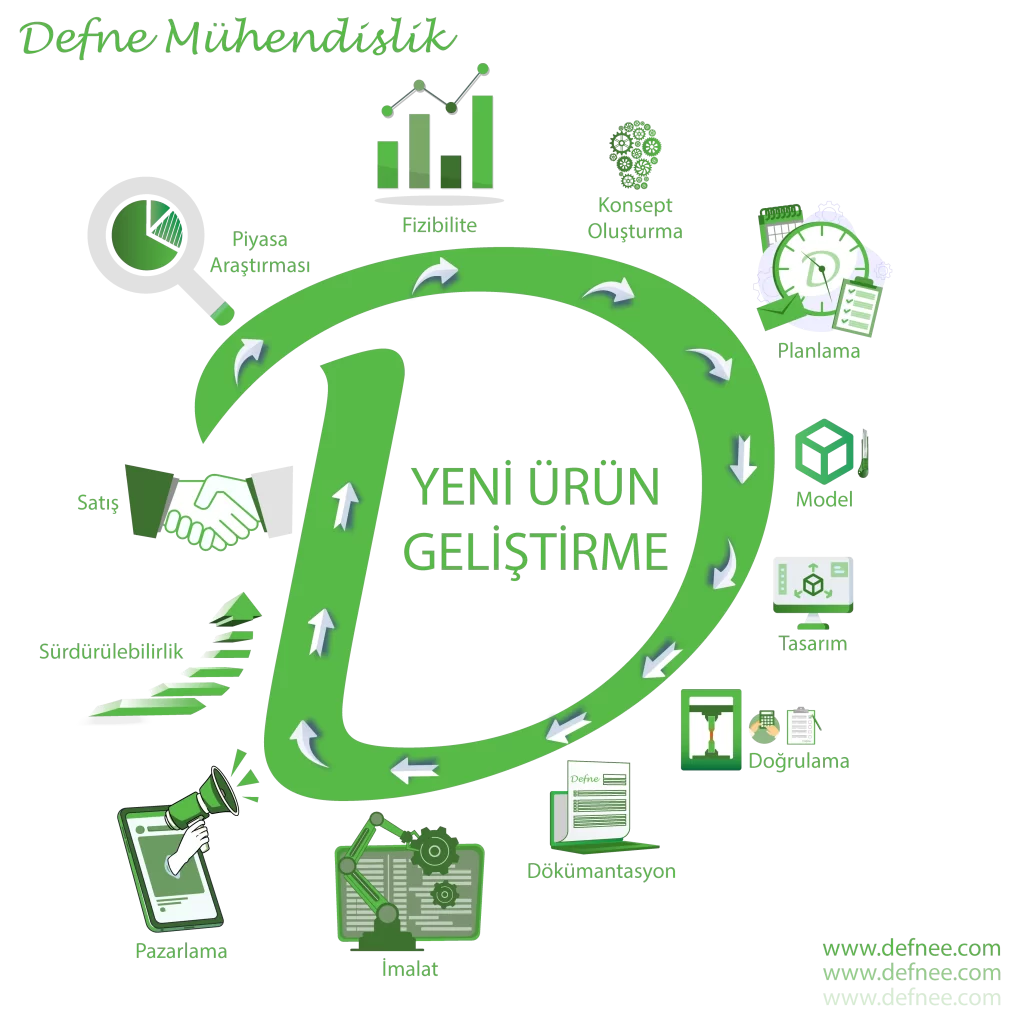

What is Product Development? What are the product development stages? Before defining these concepts and our company’s approach, what is New Product Development? Let’s summarize briefly.

What is New Product Development ?

In business and engineering, new product development (New Product Development) covers the entire process of bringing a new product to market, innovating an existing product, or introducing a product to a new market. A central aspect of NPD is product design along with various commercial considerations. New product development is generally defined as the transformation of a market opportunity into a product ready for sale.(1)

If there is an existing product and development will be done on it, we define the process as product development. If a new product is to be created and introduced to the market, we define the entire process (!) as “New Product Development”.

New product development encompasses all product design work and moves away from being design-centered.

What is Product Development?

For example; There are serious problems in the supply and maintenance of the 6-cylinder fuel pump of a vehicle engine based on old technology. The company that supplies the pumps no longer produces them, and the tolerances in the maintenance processes of the existing ones cannot be achieved. It is not possible to supply new spare parts used in the pump. In this case, the existing 6-cylinder engines may become unusable. It continues to supply fuel pumps and spare parts used in 16-cylinder engines with the same technology.

The development of an existing product for purposes such as updating, strengthening competition, and protecting market share are design-oriented studies. It is the development of the products that the company produces and trades by passing them through a design and engineering screen. In this study, design-centered studies such as material, mechanism, visuality, production methods and durability are carried out.

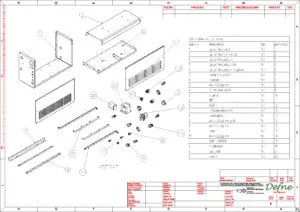

The basis of updates and development is the examination and interpretation of competing products. With the help of product SWOT (Strength Weakness Opportunity Threat) analysis, areas and opportunities for improvement are clearly identified and a road map of the work to be carried out is created. The details of similar or competing products, such as mechanism details, forms, material and production features, are obtained through reverse engineering studies. 3D Measurement

Reverse Engineering

Thanks to Retrospective Engineering studies, the fuel pumps of 16-cylinder engines were examined and it was analyzed that this structure could be used in a 6-cylinder structure, the spare parts problem would be eliminated with the improvements to be made, and the production would be met at a much more affordable cost with domestic facilities. With the help of 3D Measurement, the product was developed by improving strength, materials and special processes.

Our industry has started to use these and similar studies widely, especially in the defense industry, aviation, automotive and medical sectors.

How to Do Product Development

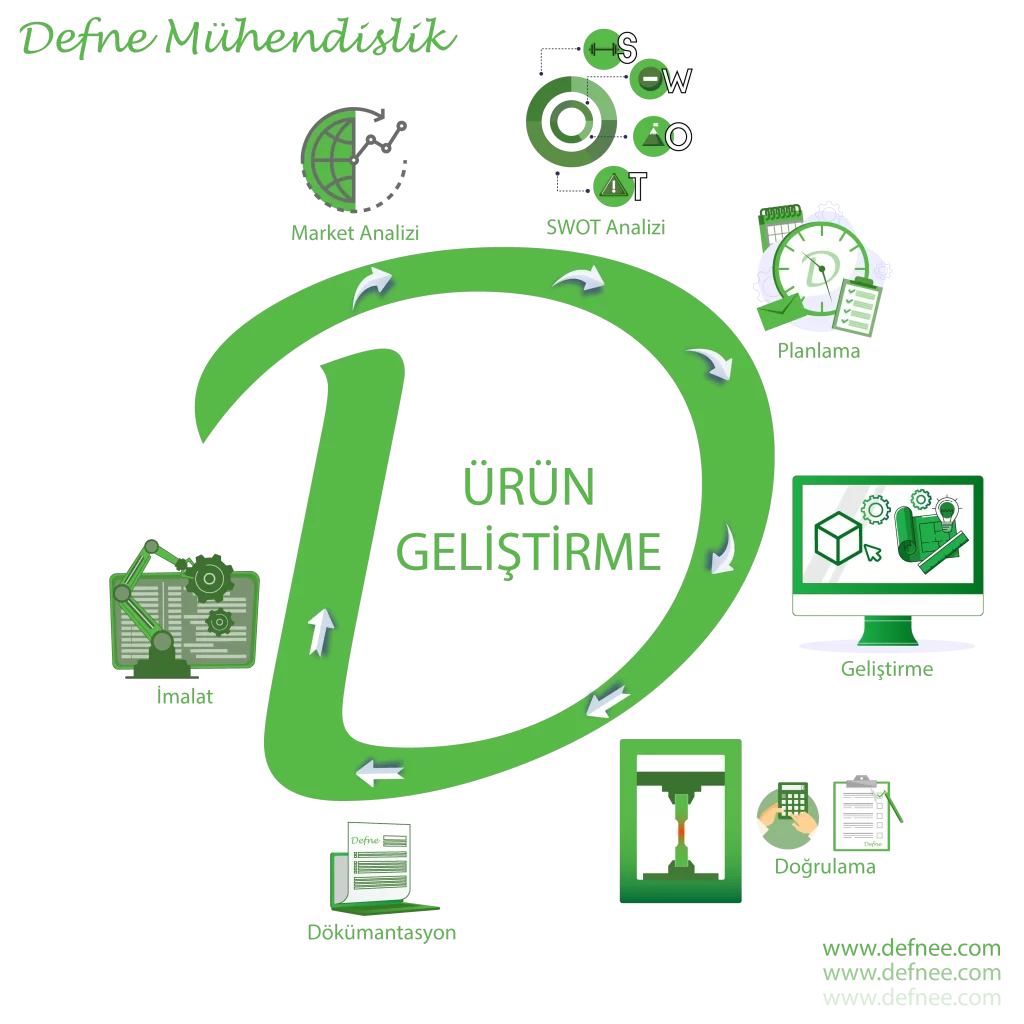

Market Analysis

Positioning the product relative to its competitors in the market. Life expectancy, determination of new markets and targets, recycling of existing customers, and product development opportunities are created in detail. This information will form the basis of the studies to be carried out. It will help clarify the objectives of the work to be carried out with design and engineering support and provide a more purposeful focus.

Swot

Generally, the analysis method used in companies’ processes and projects is based on the product. This analysis, which is based on the data of the market analysis, determines the strengths and weaknesses of the product, lists product development opportunities and threats to the life cycle of the product. The aim of this study is to determine the priority issues in development and at what level the development will be implemented. (2)

Planning

Details of the development stages of the product and the roadmap of what work will be done and how are determined at this stage. Details of studies such as Development, Verification, Documentation, Procurement, Production and Improvements are created.

Development

Material revisions, production method updates, assembly and maintenance improvements, computer-aided design studies are carried out with all sub-parts of the product for which the road map has been determined. In order for the product to fulfill its function, it is detailed by taking into account its durability and compliance with working conditions and standards. Verification studies are also carried out for critical values. In this study, material, production and assembly tolerances, quality requirements and packaging details and features are developed.

Verification

These are the studies carried out to determine and approve the working and environmental conditions of the product created as a result of mechanical design, and to ensure that its function is fully fulfilled. In these studies, the product is produced as a prototype for use and testing in the field. Prototype production is carried out from real material in accordance with the dimensions and tolerances. Depending on the place of use and purpose, similar materials and methods can also be preferred. Again, depending on the place and purpose of use, physical and/or simulation testing of the product is also a verification study. Thus, it is confirmed that the mechanical design will achieve its lifespan and function. Optimization of the product is carried out according to the results of the verifications.

Documentation

Depending on the intended use of the product, necessary revisions are made to the certifications and technical documents that may be required.

Production

Depending on the purpose and place of use of the product, the selected production method can be updated and transformed into a production method based on higher technology. Necessary production adjustments are made by reviewing the tolerances taken into consideration during the design phase and the tolerance stack analysis results.

Development efforts within the product life cycle increase both the sustainability of the product and its competitive advantage. The designs of products that have a high market share, that can maintain this share, and that can lead their competitors must be designed by teams that are experienced, constantly improving themselves, open to new ideas and knowledgeable about high technology, and follow their projects to the end.

Defne Mühendislik we carry out high quality projects with the principle of continuous development.

https://en.wikipedia.org/wiki/New_product_development

https://en.wikipedia.org/wiki/SWOT