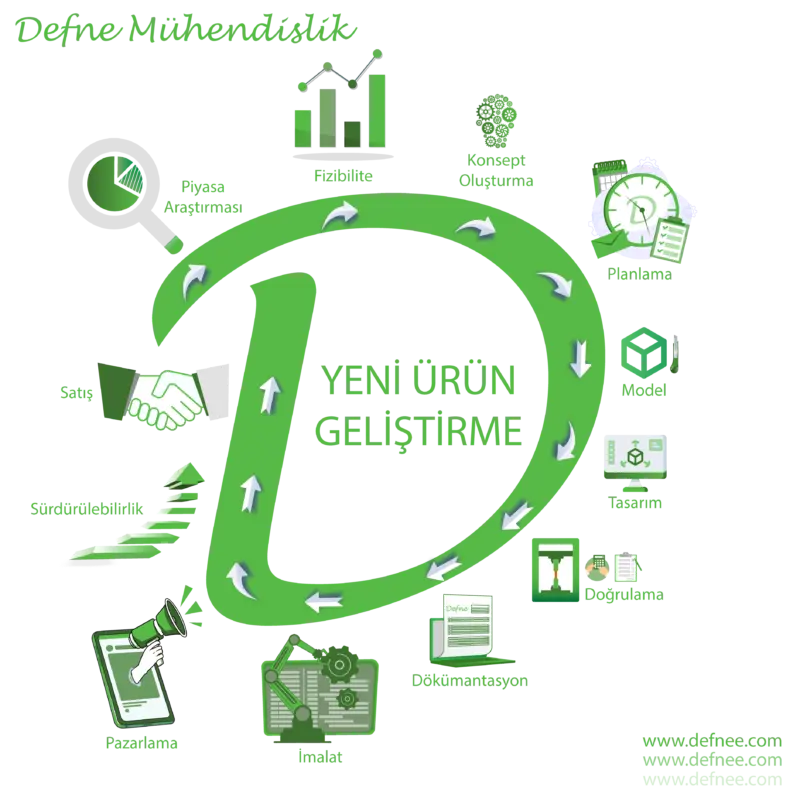

If we want to briefly explain what Product Development is and how it is done, it includes the design and production development processes of the existing product to be more functional and at a lower cost. It can also be considered as product design, but we classify the work done on an existing product as product development. Reverse Engineering studies are carried out for traded products or products that will be marketed through localization.

Product development is a definition we make for the updating, localization, development, cost optimization and similar studies of the product that the company currently produces or trades.

The company may want to introduce a product to the market in a new field where it analyzes that competition will be appropriate. At this stage, our company contributes to the creation of competitive and innovative products by examining existing products in detail and catching new trends. We carry out innovative product development projects in different sectors with our knowledge of over 16 years of experience.

In product development studies, possible competitors of the company’s current product are analyzed using the Reverse Engineering method. You can find the details of the reverse engineering study here. The basis of any development work to be carried out, whether on the company’s own product or on rival products, should be based on reverse engineering analyses. In this way, the direction of current products and trends can be determined more clearly.

What is Product Development? What are the product development stages? Before defining these concepts and our company’s approach, what is New Product Development? Let’s summarize briefly.

Product Development – Reverse Engineering

Backward Engineering – Benchmarking

One of the fastest and easiest ways to develop a product is to make various additions and changes to existing similar products. The general opinion about reverse engineering is that it is a “COPY METHOD”. However, reverse engineering is used far beyond copying by digitizing a physical product. Retrospective Engineering is a design and development method used in the development of products or subsystems in many different sectors such as Automotive, Aviation, Defense, Electronics, Energy, White Goods, Cinema.

One of the most widely known examples of Reverse Engineering; During the second world war, British and American forces realized that the Germans had excellently designed gasoline canisters. They adapted these tin cans to themselves by backward engineering. The cans were popularly known as “Jerry cans.”

A similar example in aviation is; Tupolev Tu-4, designated Bull by NATO, was a Soviet piston strategic bomber that served the Soviet Air Force from the late 1940s to the mid-1960s. It was created by backward engineering of the American-made Boeing B-29 Superfortress. Ref( 2)

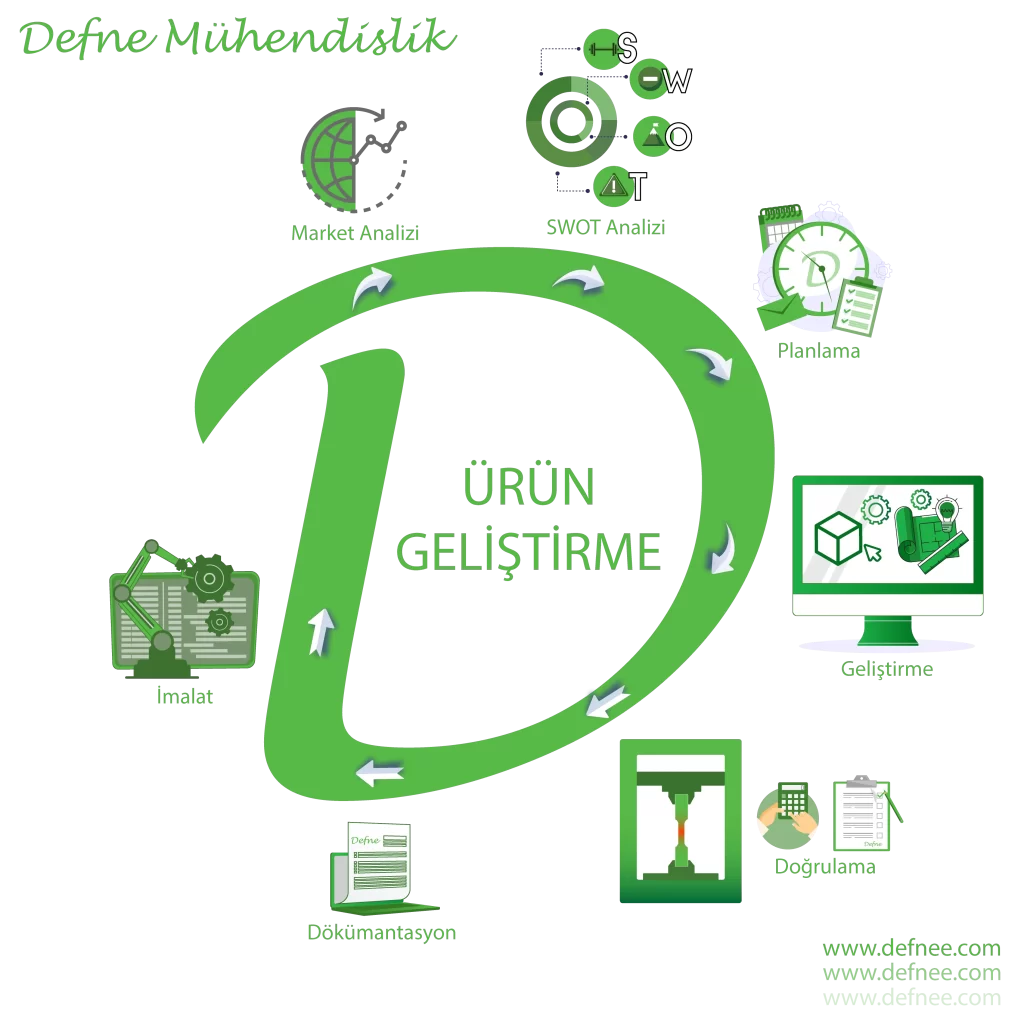

Benchmark – Comparison

Retrospective Engineering is used to examine competing products and make comparisons. Creating SWOT analyzes of products and subsystems is the first stage of my comparison. The list of features to be used in comparison is created depending on the product’s function, positioning in the market, production method and design. Some of the criteria that should definitely be included in comparisons are; Material, mechanical properties, production method, production processes, maintenance, repair and recycling must be included in the reporting. Product Lifecycle Management, also known as PLM, is also known as Product Life Management Cycle in Turkish. In comparisons, creating the product’s PLM life cycle with all its details will bring sustainable success.

Design-related comparisons can be made in two different ways. The first is redesign, that is, product development work by improving a product and differentiating and updating it for the same purpose. This study includes studies that will enable the evaluation of existing products such as material change, production method and development of product life processes. Another form of comparison regarding design is; These are studies that will be carried out using the forms, production and processes of different products for a completely new product.

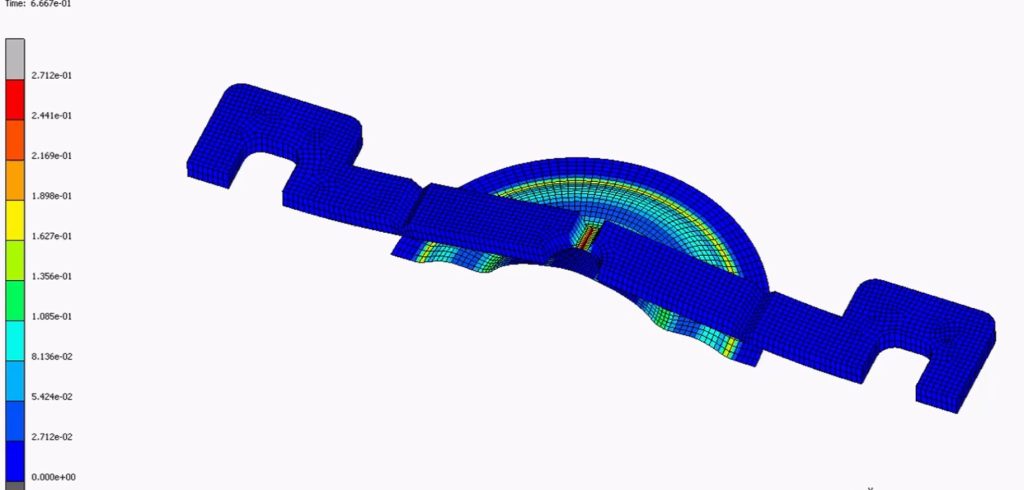

One of the best examples of where benchmarking is used in redesign work is the domestic aircraft seat design. In this study, two different model seats were transferred to the computer environment with all their details. All details of the seats, such as material, mechanics, function, ergonomics and production methods, were examined in a computer environment. Through patent research, the works that companies have highlighted and protected in their designs have been examined in detail. The knowledge required to ensure environmental and working conditions was also gained through benchmarking. Existing designs that passed the tests were verified by simulation, and the application of simulations of new concept designs with these principles increased the accuracy to the highest level.

The concept and details of the new design were created with innovative approaches in all details, not just limited to these issues.