Quality control service is provided by comparing the 3D dimensioning (Optical scanning) result or point cloud and/or STL data taken from any measuring device with the CAD model and reporting the differences. It is especially used in reporting for dimensional quality control of free-form parts, using CAD modeling as a reference. The sensitivity and time loss experienced in measuring shaped surfaces in CMM systems is overcome very quickly and precisely with optical scanning.

Many different methods are used to transfer the CAD model and measurement data to the same reference. The two main methods most used are:

- Reference overlapping: Two data are superimposed with the help of planes, vectors and points that form the reference in the CAD data of the product, apparatus or mold and the measured point cloud.

- Best fit registration: With the placement called “Best Fit”, the point cloud is automatically registered in the most suitable geometric way to the CAD data coordinates.

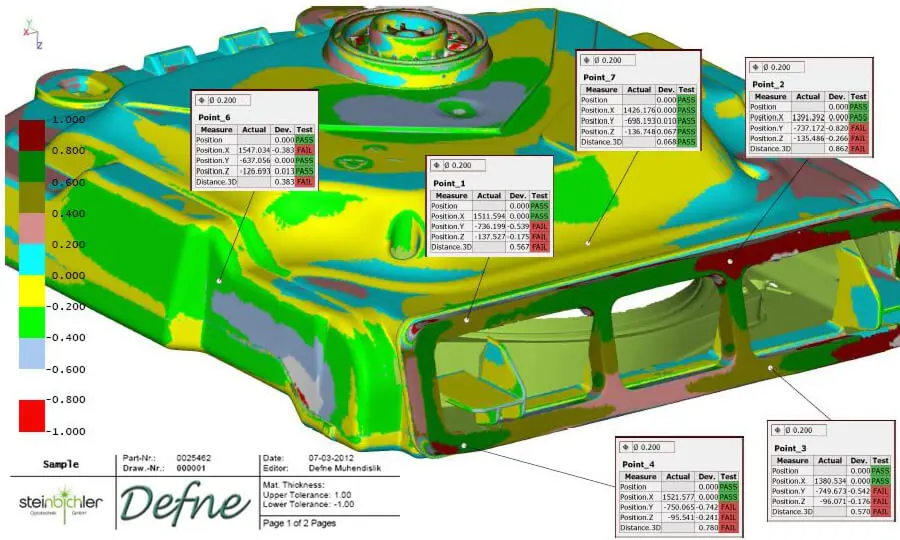

The differences in the CAD model of the measurements taken in a three-dimensional digital environment are given as color scales. Measurements such as perpendicularity, circularity and geometric differences are made in the desired regions or sections of the scan data.

The final report is delivered to customers in the form of graphic images and tables.